What or how would you like to grab?

With our modular Gripper System, we have the right gripper for every application, whether, for example, flat parts, gripping in a bore or flexible parts. Here you will find inspiration for a wide range of applications.

Vacuum Pads

The suction pad (vacuum cup) SG is the simplest and most cost-effective way to handle a component. There are various designs, materials and sizes. It can be attached directly to the profile, rigid, twistable, spring-loaded and via a lifting unit.

Gripper

The GZA grippers are primarily used to grip the sprue. There are different types of grippers available. However, the component can also be gripped with the gripper. The gripper can be a good alternative to parallel grippers.

Gripper Fingers

If the demolding forces or the handling weight is too great that the vacuum suction cup is no longer sufficient, the GFI gripper fingers are used. There are different sizes with different finger shapes. Functional range: Single-acting, double-acting with or without self-locking. The modular system offers a wide range of accessories.

Parallel gripper

If inserts or bushings, rings or screws have to be picked up precisely, PAG impact grippers are used. A distinction is made here between different sizes, number of gripper fingers and stroke sizes. The adaptation options from the modular system are also used optimally here, both in the gripping direction and in the attachment direction.

Inner bellows gripper

If components are gripped via a bore, the IBG inner bellows gripper can be used. Different sizes are available. The operating principle is pushing / pulling. The inner bellows grippers can be very easily integrated into the gripping system via the extension thread.

Magnetic gripper

If the component is ferromagnetic, it can be easily handled with magnetic grippers MGR. Handling weight per gripper from 200g - 3000g. ES there are electrically or pneumatically driven versions. Via the prism directly on the body, the unit can be attached to PreciGrip profiles.

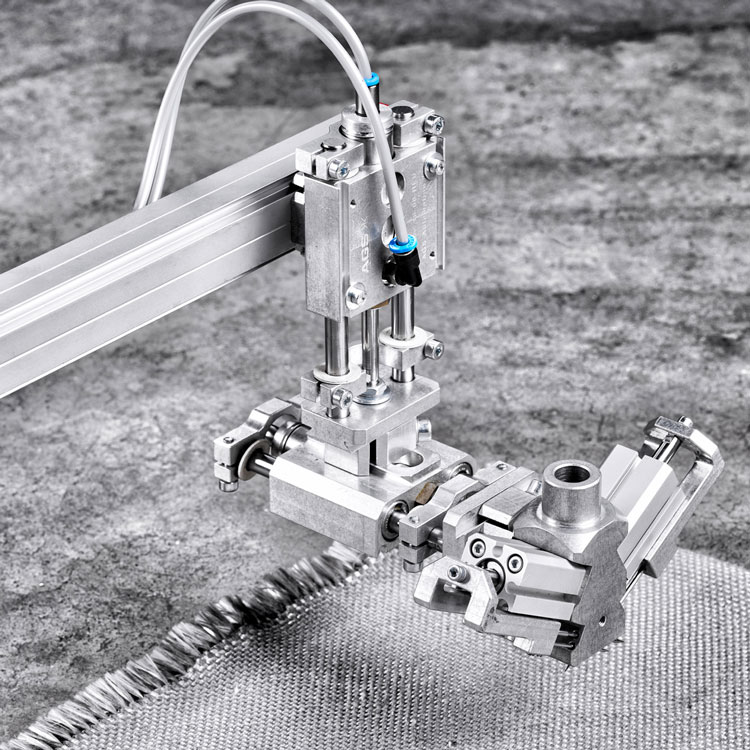

Textile gripper

Textiles or flexible parts, such as textiles, foams, SMC (Sheet Molding Compound), nonwovens are handled with needle grippers NAG. 4 to 32 needles can be used. The penetration depth of the needles can always be easily adjusted. The connection is made via a prism on the body of the needle gripper.

Textile gripper

Soft components (textiles, show fabrics, insulating materials, woven fabrics, SMC (Sheet Molding Compound), etc.) are gripped with NAG needle grippers. These are all pneumatically driven. There are variants with double stroke which means that the needle can make 2 different long movements. A combination with the standard stroke units is also possible.

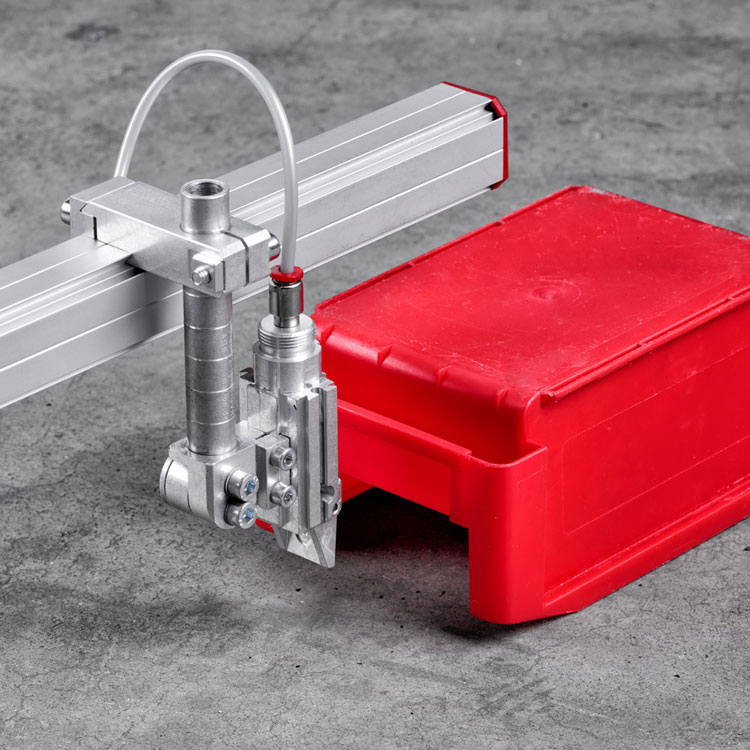

Cutting nippers

ANS nippers are used when components have to be separated. These are also called sprue cutting nippers because they are often used for sprue cutting. There are different sizes and cutting inserts with different cutting angles. The sprue can also be held at the same time as trimming.

Centering lock

If the gripper or the unit is to be centered and locked, the centering and locking unit ZVE is used. These are pneumatically driven, single-acting or double-acting. Interrogation is possible. This unit can also be used at manual workstations for changing supports.

Parts inspection

The presence of components in the gripper is monitored with the AGS part controls TEK. They are mostly used when no monitoring with a vacuum suction cup (vacuum switch) can take place. For the part controls there are a lot of accessories in the program, mounting material, cables, plugs and distributors.

Attendance check

The TEK telecontrol can also be used for flow monitoring. Switching distances of 1 - 600mm can be realized. Mounting options are available here for almost all sensors and cameras on the market.